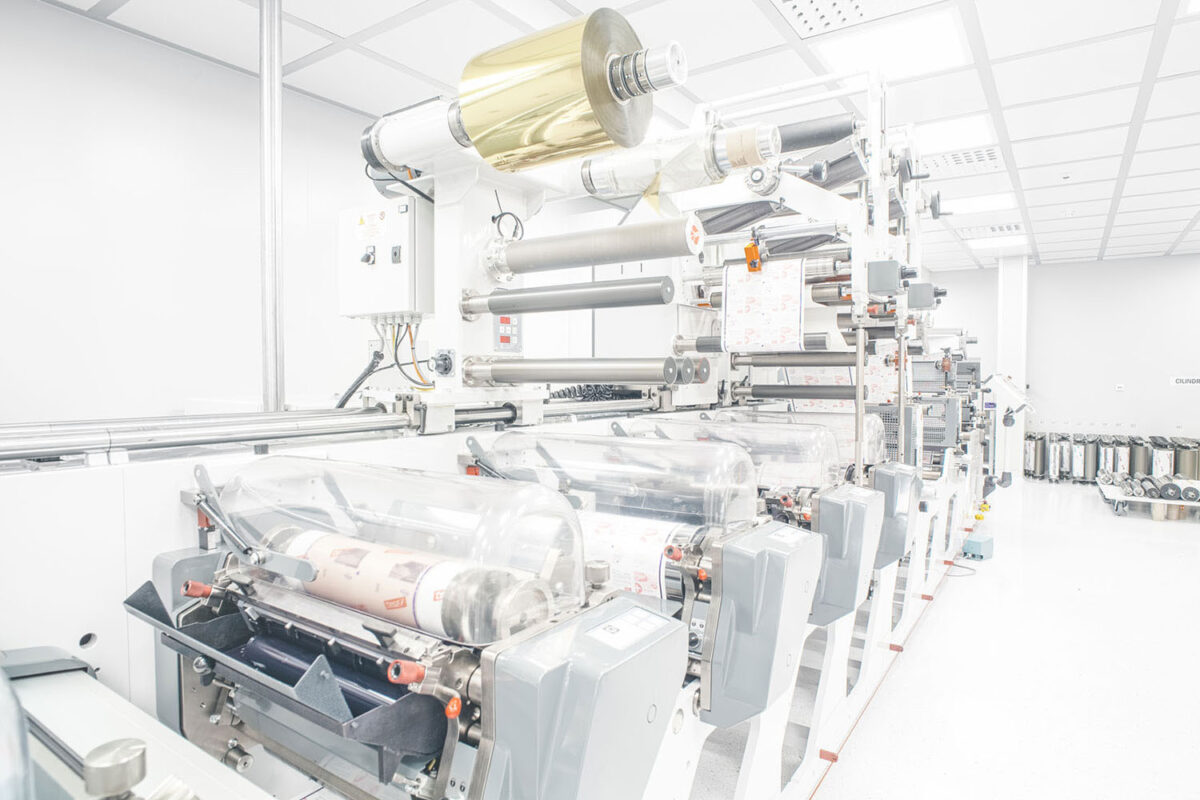

In 2013, our company set up a clean room – an area that requires maintaining meticulous microclimatic conditions. Pressure monitoring and air flow are fully computer controlled, and all the necessary parameters are available at all times. These parameters can be checked at all stages of the product manufacturing process, and they show the current conditions in the clean room:

- pressure,

- airflow,

- temperature,

- relative humidity, etc.

This type of printing area fully complies with the highest standards that are required in the:

- pharmaceutical,

- chemical,

- cosmetic and

- food industries

At the end of 2022, we obtained the ISO 15378 certificate, which outlines the requirements for a quality management system and is used for primary packaging materials for medicinal products. This demonstrates that we are capable of consistently providing products and services that meet both customer requirements as well as legal and regulatory requirements. We do business with verified suppliers because we want to increase customer satisfaction through efficient use of the system, thereby ensuring high-quality, safe and effective medicine (including primary packaging in contact with medicinal products).

Read more about flexo printing here.