The printing industry is involved in producing various printed materials, such as magazines, newspapers, advertisements, informational leaflets, notepads, brochures, and postcards. The primary consumable material used in this industry is paper. The quality and aesthetics of the final product depend on its technical and decorative properties, which depend on the paper types.

When choosing paper for printing in a printing house, various characteristics are taken into account. Let’s consider the main ones:

Density

One of the crucial characteristics is density, which equals the mass of a sheet with an area of 1 square meter.

Types of paper based on density and their applications:

- 40-70 g/m2 – Newsprint. Provides an economical option for producing printed materials like leaflets, newspapers, and forms.

- 80 g/m2 – Standard office paper. In demand for printing documentation, corporate stationery, and notepads.

- 90-115 g/m2 – Coated paper. Used for creating advertising materials and glossy magazines. Full-color printing on coated surfaces looks bright, sharp, and vibrant.

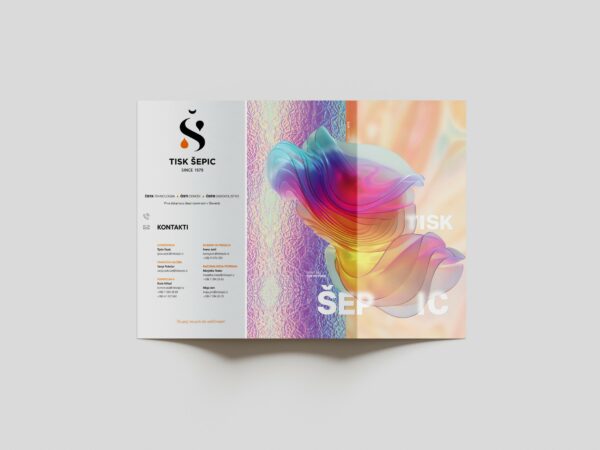

- 130-150 g/m2 – Heavyweight paper, used for full-color brochures with images, premium brochures, and high-quality leaflets.

- 170-200 g/m2 – Rigid materials, used for making calendars, albums, catalogs, premium-class brochures, invitations, and programs.

- 250 g/m2 – Used for standard business cards, postcards, and invitations.

- 300 g/m2 – A suitable option for printing exclusive business cards.

Whiteness

This characteristic is determined by the surface’s ability to reflect light waves and falls within the range of 50-98%. The higher the level of whiteness, the brighter and clearer the full-color image appears, and the more expensive the material is.

Matte/Glossy Finish

Varieties of printing paper with a glossy surface are considered more attractive compared to matte materials. However, due to eye strain from gloss, matte pages are preferred for multi-page printing, especially with small fonts. Glossy materials are chosen for printing various images: photographs, logos, and illustrations.

Transparency

This characteristic indicates how much light a specific type of paper can transmit. High transparency is a negative quality in a material as it prevents printing on the reverse side of the sheet.

Texture

Paper surfaces can be smooth, rough, or embossed.

Classification of Paper Used in Printing

The choice of printing material in the printing industry depends on factors such as the printing type, color, presentation of text or illustrations, and budget.

Offset Paper

Initially used only for offset printing, this type of paper is now in demand for other printing technologies as well. It has a density ranging from 65 to 280 g/m2 and is characterized by high cellulose content, a white color, machine smoothness, a matte surface, and no glare under light. Offset paper is suitable for writing and drawing with pencils and ballpoint pens. It is used for embossing, and lamination is rarely applied. However, images printed on offset paper may not appear as bright and sharp as those on coated materials. It is commonly used for printing notepads, books with text and illustrations, albums, envelopes, and paper bags.

Newspaper Paper

Also known as newsprint, this thin paper has a grayish or yellowish tint and a low density of 40-52 g/m2. It is used exclusively for offset, color, or black-and-white printing. Newspaper paper is designed for short-term use and is not intended for long-term storage. It tends to yellow, age, and become brittle over time.

Carbonless Paper

This multi-layered material is used for printing forms and has a special chemical coating that allows information from one sheet to be copied onto another without the need for carbon paper. Carbonless paper is thin, with a density not exceeding 60 g/m2, and is mainly used for offset printing. Digital printing technology may not be suitable for handling such thin sheets.

Coated Paper

Coated paper is called so because it has a thin layer of kaolin, chalk, and binding agents applied to it. It is used to produce advertising and informational brochures, leaflets, brochure covers, posters, magazines, wobblers, calendars, business cards, tags, and labels. Coated paper can have either a matte or glossy surface, and its density ranges from 60 to 245 g/m2.

The following printing technologies are applied to coated sheets:

1. Offset Printing: Coated sheets with their bright white surface are an excellent fit for offset printing, where all colors, shades, and gradients appear striking.

2. Digital Printing: Suitable for sheets with a density of 90 g/m2 and above.

3. Silk Screen Printing: Coated paper effectively retains images produced by silk screen printing.

Coated sheets are not used in inkjet printing, as the ink tends to smear off the smooth surface.

Designer Paper

Designer paper is used for exclusive artistic and design projects, such as gift certificates, presentation brochures, business cards, covers, and art books for artists. It is produced from various raw materials using specialized techniques. The most popular types include:

1. Efalin – This textured material is treated with a special impregnation that enhances its durability. It is used for finishing the front side of book covers and making bags.

2. Touch Cover – This dense paper of representative class has a unique tactile effect, simulating rubber. It is used for creating business cards and greeting cards.

3. Majestic – Durable metallized sheets designed for high-strength printing products.

4. Eurocolor – Designer colored cardboard embellished with embossing. It is used to create exclusive business cards, folders, and gift packaging.

Choosing the printing method on designer materials is best entrusted to a professional.

Kraft

One of the oldest types of paper is kraft paper, composed of long-fibered, slightly cooked sulfate cellulose. Today, thanks to modern technologies, kraft paper can be produced with various effects and prints. This material is mainly used for creating packaging – bags and envelopes. The surface can be brown or bleached.

Types of cardboard used in the printing industry for manufacturing printed products.

Cardboard is characterized by high density, stiffness, strength, and the ability to retain its shape. This material is well-suited for various finishing works such as blind and foil embossing, varnishing, and lamination. It is used to make business cards, laminated pseudo-plastic cards, book covers, and packaging.

Cardboard can be single-sided and double-sided. Single-sided cardboard is used for making folders with logos, notebook covers, and calendars. Double-sided cardboard, which is more expensive, is in demand for producing printed products with high aesthetic requirements, such as business cards, greeting cards, invitations, and premium-class packaging.

In the world of printing, paper isn’t just a canvas; it’s the brushstroke that brings your ideas to life. So, remember, the next time you launch a printing project, the right paper choice can make all the difference in leaving a lasting impression. Choose between paper types wisely!